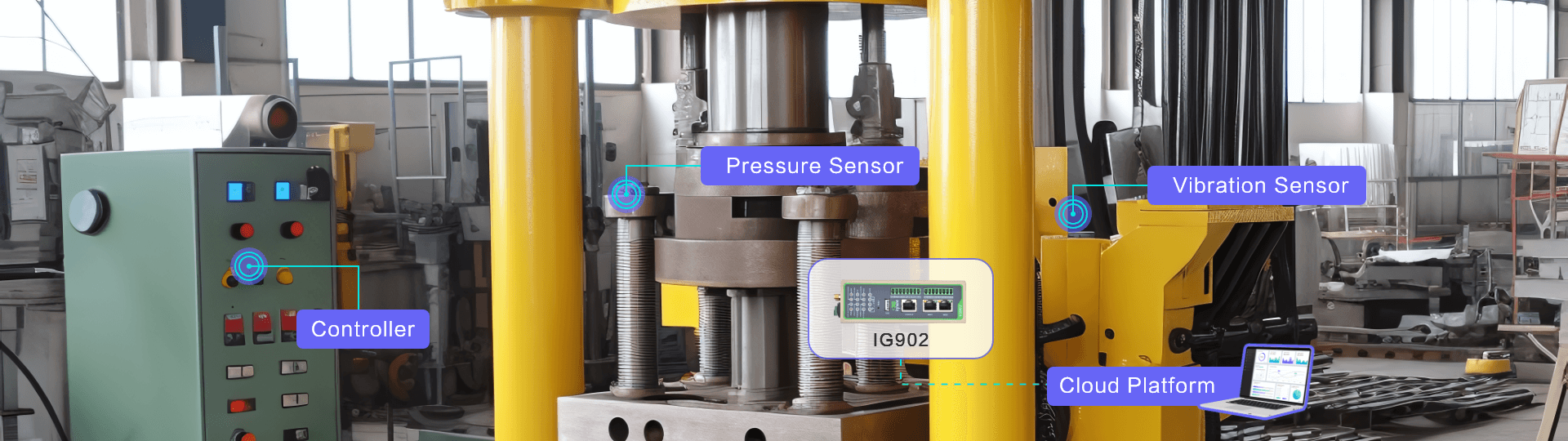

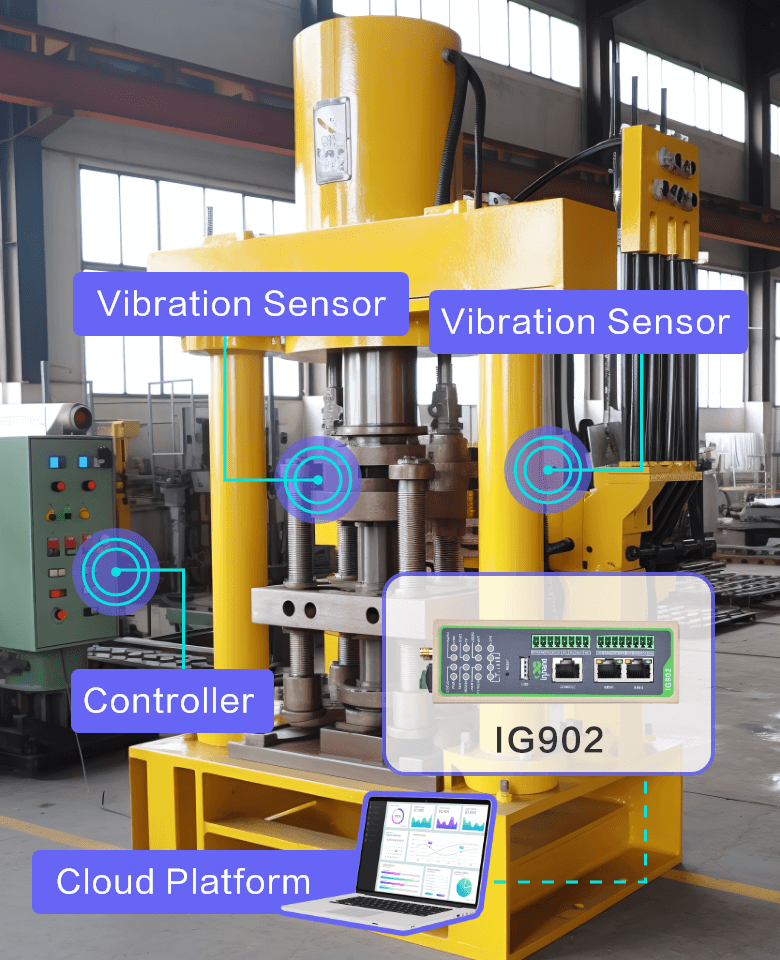

Remote Monitoring of Hydraulic Press

Hydraulic presses are large and complex, requiring careful operation while in use. With powerful edge computing capabilities and support for multiple industrial protocols, the IG902 IoT edge gateway offers a simple, complete and efficient remote monitoring and diagnostic solution for hydraulic equipment.

Background

Large hydraulic equipment is indispensable in the construction of infrastructure such as metro lines. Their large size, complex structure, and underground working environments expose their risk if not used properly. Therefore, it is necessary to apply advanced monitoring and diagnostic technology for machinery.

An online monitoring system is expected not only to predict equipment failures, but also optimize itself. InHand Networks offers a simple, complete and efficient remote monitoring and diagnostic solution for hydraulic equipment.

Customer Requirements

Remote Monitoring

Achieve remote monitoring of hydraulic press, including real-time data collection, anomaly detection, and remote operation functionality.

Optimize Production Capacity

Improve the operational efficiency of production facilities, reduce downtime, and increase production capacity.

Predictive Maintenance

Optimize equipment performance through data analysis, proactively identify potential issues, and predict maintenance needs.

Network Security

Ensure the security of the monitoring system, guarding against potential network attacks and unauthorized access.

Solution

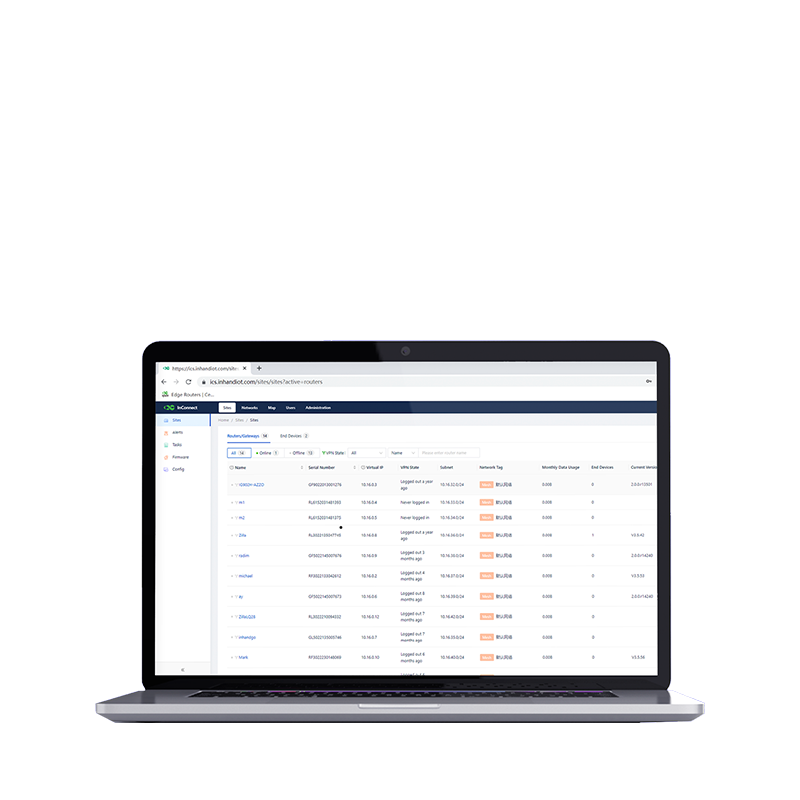

Sensors, hydraulic press, controllers and other devices on site are connected to the edge computing gateway via their respective protocols. With Python custom development feature, the customer can define the criteria for data processing. After data collection and pre-processing locally, the IG902 IoT edge gateway then sends the filtered data to the cloud via MQTT for further analysis.

Benefits

Powerful computing capabilities

Built with ARM Cortex-A8 processor, the IG902 edge computing gateway features powerful edge computing and data analysis capabilities. Data collected from PLCs can be preprocessed on the edge, relieving the load in the cloud while quickening response to the data source.

Easy configuration for data acquisition

The IG902 IoT edge gateway supports multiple PLC protocols and major IoT clouds. Onsite devices can be connected to the cloud through simple configuration in minutes.

Fast, secure and reliable connectivity

Available with LTE CAT4/CAT1 cellular networks, Wi-Fi and wired connection, multiple link redundancy technologies and security strategies, the IG902 provides fast, secure and uninterrupted network access, ensuring that devices are constantly connected.

Built for developers

Python programmable, the IG902 IoT gateway enables users to custom their own applications and thus make better use of the data for their business.