IoT Solution for Photovoltaic Cleaning Robots

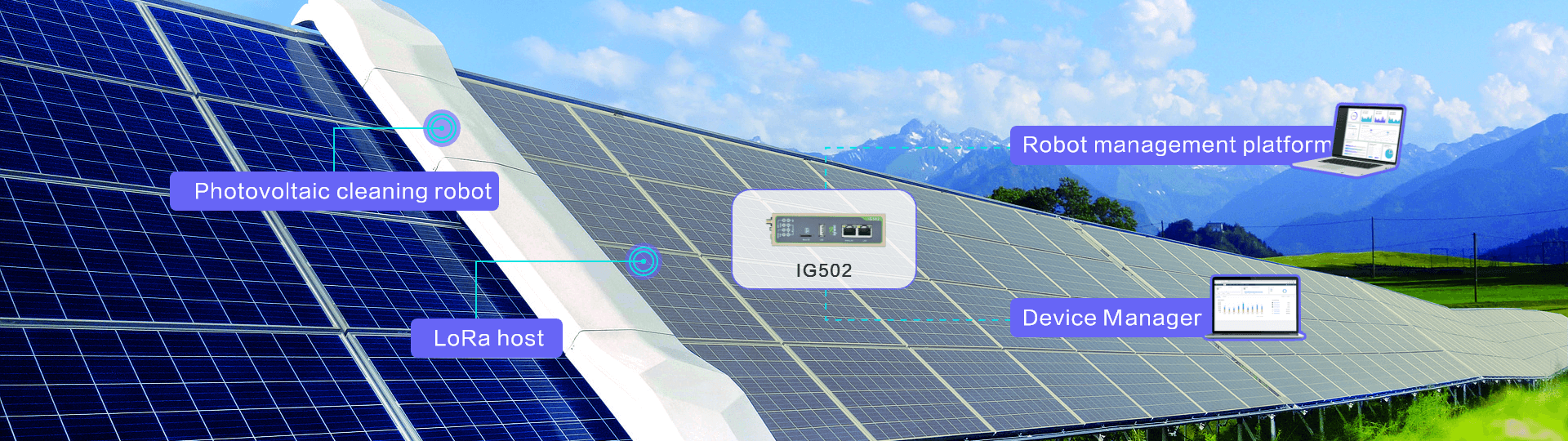

The IG502 and the Device Manager, together with the customer’s robot management platform, enable remote centralized monitoring and management of robots.

Background

As the use of solar power generation continues to expand, solar power plants are growing in scale and number. To maintain their efficiency, regular cleaning of solar panels is essential. However, manual cleaning is time-consuming and inefficient. To enhance cleaning efficiency and reduce labor costs, the solar panel cleaning robot has emerged, which autonomously perform cleaning operations, effectively removing dust and dirt from solar panels to ensure the plants’ maximum power generation capacity.

Nevertheless, as solar power plants scale up, maintenance engineers face challenges of monitoring and managing all robots simultaneously and promptly responding to robot malfunctions. Additionally, conducting remote diagnostics and upgrades efficiently poses difficulties. Furthermore, effectively analyzing operational data and performance metrics of the robots proves essential for accurately adjusting and optimizing maintenance plans and cleaning strategies.

Customer Requirements

Remote Operation and Control

Remotely operate and control the robots, including starting, stopping, and adjusting cleaning paths. Enable centralized management and control of multiple robots.

Fault Monitoring and Remote Diagnostics

Real-time monitoring of the robots’ operational status and performance metrics. Promptly alert and notify in case of any malfunctions or anomalies, facilitating timely fault diagnostics and repairs.

Data Collection and Analysis

Continuously collect and record operational data of the robots, such as working hours, cleaning effectiveness, and energy consumption. Analyze this data to understand robot performance, optimize cleaning strategies, and provide better technical support and services.

Remote Upgrades and Maintenance

Remotely upgrade robot firmware and software, as well as configure and adjust parameters. Enhance maintenance efficiency, reduce workload for maintenance personnel, and lower maintenance costs and cycles.

Solution

InHand provides a comprehensive solution, combining a gateway of IG502 edge computing gateway and the Device Manager cloud. Together with the customer’s existing robot management platform, this solution enables remote centralized monitoring and management of robots.

Distributed robots connect to the LoRa host via LoRa, and the IG502 links to the LoRa host through RS485, enabling communication. Using Modbus RTU protocol, the IG502 collects data from multiple robots, filtering it to save upload bandwidth. It detects alarms and converts data for the robot management platform. Customers can also configure the IG502 to respond to platform commands, enabling unified modification of robot parameters and batch upgrades.

Customers can remotely and centrally monitor robots via the management platform, accessing real-time data on status, efficiency, and cleaning progress. Analyzing performance data enables timely response to malfunctions, optimizing cleaning strategies and maintenance plans for improved effectiveness. Remote firmware upgrades enhance maintenance efficiency.

The Device Manager enables unified management of the IG502, facilitating remote batch upgrades, configuration, and diagnostics, significantly reducing maintenance efforts after IG502 deployment.

Capabilities

Cost-effective Communication Device

The IG502 offers robust processing power, delivering excellent performance with remarkable cost-effectiveness. It allows connection to dozens of robots simultaneously, enabling efficient data management and monitoring.

Flexible Edge Data Processing

The IG502 provides flexible edge data processing capabilities, allowing customers to configure functionalities based on their specific needs. It can handle data change detection, alarm monitoring, format conversion, and customizable features to adapt to various application scenarios.

Efficient Integration with Devices and Clouds

Supporting various industrial protocols, the IG502 seamlessly connects to IoT cloud platforms like AWS and Microsoft. It caters to diverse device data collection requirements, ensuring smooth integration with customers’ chosen cloud platforms.

Ensuring Data Reliability and Integrity

The IG502 supports offline data caching, storing data when the network is down and seamlessly resuming transmission upon network restoration. This ensures data integrity and continuity. With its 8GB eMMC storage and expandable Micro SD card support, the IG502 offers ample data storage to meet diverse customer requirements.