Remote Monitoring Solution for Air Compressors

Featuring powerful edge computing capabilities, support for multiple industrial protocols and IoT clouds, and industrial design, the IG502 delivers a reliable remote monitoring solution for air compressors.

Background

Air compressors, as large-scale mechanical equipment, generate substantial maintenance and troubleshooting needs over prolonged use. High power consumption and maintenance costs amplify the impact of failures, potentially leading to significant losses due to delayed repairs and extended downtime.

A prominent air compressor manufacturer is dedicated to enhancing product quality and user experience through innovative technologies. Recognizing the benefits of network connectivity, they enable maintenance personnel to remotely monitor compressor operations, detect anomalies promptly, and proactively address issues. This strategy minimizes downtime, enriches customer service, and enhances overall value.

Customer Requirements

Real-time Monitoring and Remote Control

Enable real-time acquisition of key air compressor parameters, such as temperature, pressure, and speed, through different protocols. Allow remote control to adjust parameters and optimize the production process.

Fault Diagnosis and Predictive Maintenance

An intelligent system analyzes collected data to diagnose potential faults, issuing timely alerts to prevent production interruptions and equipment damage.

Data Analysis and Reports

An advanced data analysis platform processes, analyzes, and visualizes operating data. It supports report and chart generation, enabling clients to monitor production efficiency, quality metrics, equipment utilization, and drive continuous improvement.

Solution

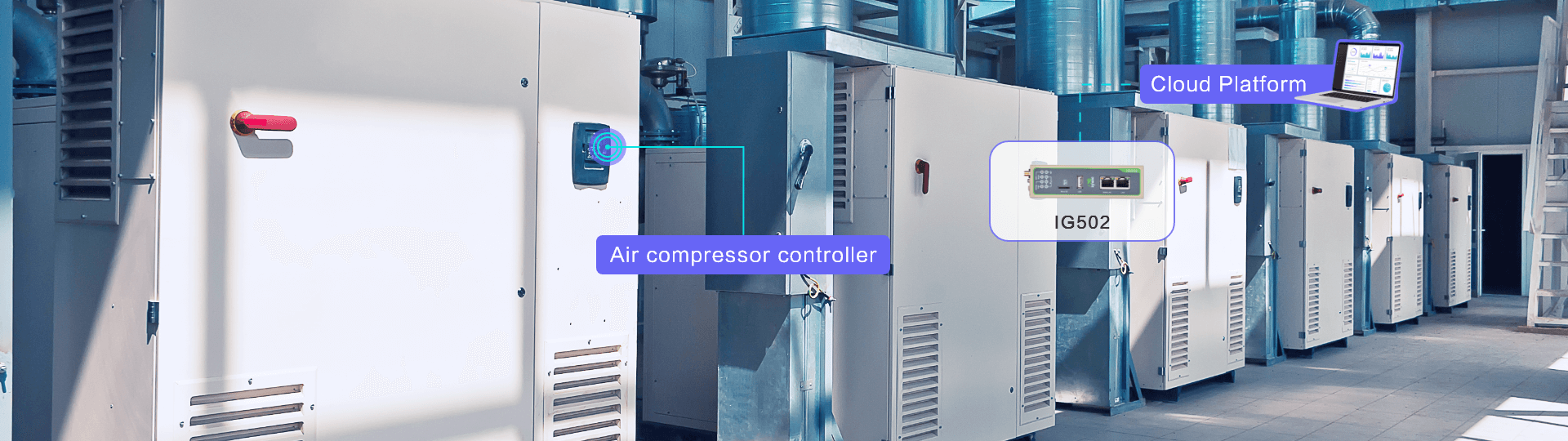

The system consists of an air compressor, the InGateway502 (IG502), and a remote management platform. The IG502 connects to the air compressor controller to collect key field data such as oil temperature and lubricating fluid in real time. It transmits this data to the remote management platform for analysis and processing through the 4G network. Customers can view, count, and analyze data at any time via computer or mobile phone.

Maintenance teams establish maintenance channels through the software with the on-site air compressor. After logging into the client software, they can perform remote maintenance and online monitoring. Timely preventive maintenance helps discover and resolve issues before failures occur, reducing downtime and maximizing equipment service life.

Capabilities

Supports Major Protocols and Clouds for Easy Monitoring

The IG502 supports Modbus TCP/RTU, EtherNet/IP, ISO on TCP, OPC UA Client, and other major industrial protocols, making it easy to send device data to the cloud for remote monitoring and preventive maintenance, reducing operational costs and improving customer satisfaction.

Python Programmable, Built for Developers

The IG502 comes with an embedded secondary development platform that supports Python programming, enabling customers to effortlessly implement specific business logic and achieve personalized functions or services.

Easy Management for Large-scale Deployment

The IG502 supports web interface configuration and enables easy setup. The Device Manager efficiently centralizes the management of numerous devices, allowing users to monitor gateway status anytime anywhere.

Stable and Reliable Network Keeps Devices Always Online

The IG502 ensures excellent and stable network service for unmanned IoT sites, guaranteeing uninterrupted connectivity and device reliability.

- Dual SIM, automatic switch to high-quality carrier’s network;

- Multiple-level link detection mechanism for link status monitoring, automatic redial and self-recovery from faults;

- Embedded watchdog technology ensures normal operation.

Powerful Edge Computing Capabilities Enable Intelligent Data Processing

The IG502 is equipped with a powerful ARM Cortex-A8 processor, running at 600MHz with 512MB RAM and 8GB eMMC. This robust edge computing capability enables intelligent data processing, optimization, real-time response, and smart analytics for on-site devices.

Products

More Applications

Featuring strong data transmission and edge computing capabilities, the IG502 offers a remote monitoring solution for distributed machines and enhances efficiency for facility operation and maintenance.

The IR915 connects one or more field PLCs to form a field network of concrete mixing equipment, collect data of field controllers and sensors, and upload the data intelligently with local caching mechanism. In this way, data reliability, real-time and security are ensured, with saved data flow costs.

To better monitor the status of bearings and conduct preventive maintenance, InHand Networks delivers a solution featuring the IG902 edge computing gateway, helping acquire real-time data of the bearing status, upload data to the cloud for analysis and maintenance.