Remote Maintenance of Elevators

The remote maintenance solution of elevators enables real-time, remote, and visual elevator operation monitoring, ensuring the safety of elevator operations.

Background

Elevators provide immense convenience for today’s urban residents, shoppers, tourists, and more. However, ensuring their safe operation and maintenance poses challenges. Leveraging IoT technologies, the remote networking solution of elevators enables remote oversight, emergency alerts, and prompt repairs, enhancing safety with reduced costs.

A maintenance company seeks to enhance elevator safety through networking, enabling remote monitoring and cloud-based management to optimize efficiency and reduce labor costs.

Customer Requirements

Fast and Reliable Connectivity

4G and Wi-Fi need to be enabled for network connectivity.

Real-time Location Tracking

The solution should support GPS/ base station positioning, helping keep track of the devices.

Remote Management

The solution is expected to enable cloud management, so that device monitoring, management, maintenance and upgrading can be done remotely.

Solution

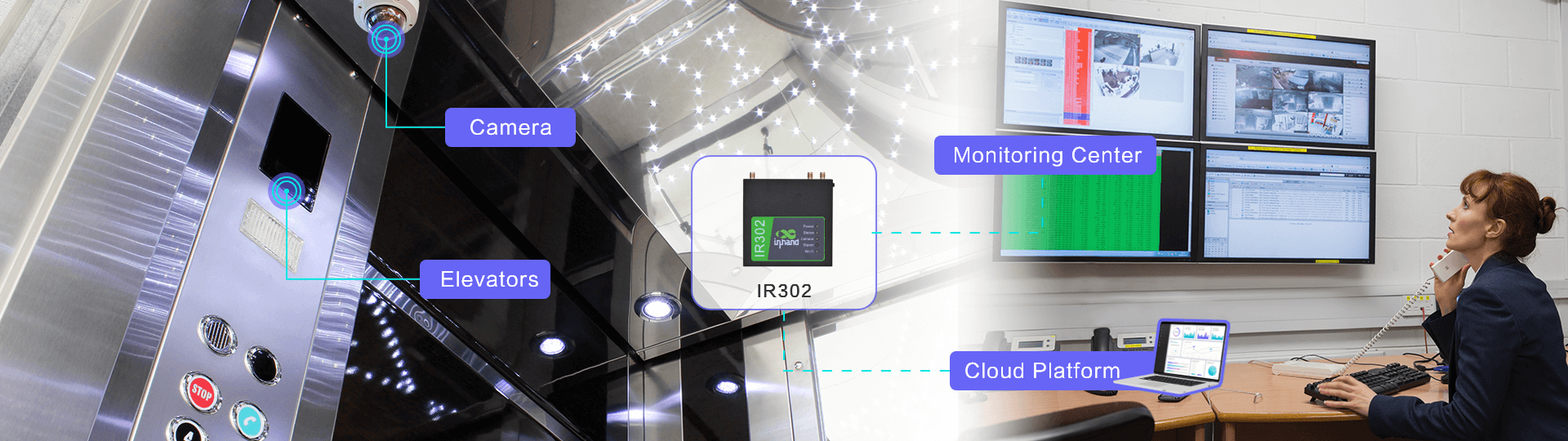

The solution consists of data acquisition, network communication, and a platform data center. The IR302 industrial router collects through 4G networks elevator operational data and real-time images from cameras and sensors at the data collection layer. This data is then transmitted in real-time to the platform data center. Through big data analysis and integration with external systems, it enables remote elevator management and predictive maintenance. This, in turn, reduces maintenance costs and elevator failure rates, ensuring the stable operation of elevator equipment and passenger safety.

Benefits

Robust Networking Capability

The IR302 industrial router is available with wired LAN/WAN, Wi-Fi, and high-speed cellular 4G network access, catering to various connectivity needs.

Stable and Reliable Operation

With multi-layer link detection, the IR302 monitors connections and enables automatic reconnection and fault self-healing, ensuring uninterrupted network service for unmanned operations.

Cloud Management

Integrating the Device Manager, the IR302 industrial LTE router enables remote deployment and easy on-site control.

Industrial-grade Design

The IR302 operates within a temperature range of -20 to 70°C and IP30 protection rating, and accepts power input through 9-36V industrial terminals, making it suitable for demanding environments.