Remote Monitoring of CNC Machines

Computerized numerical control (CNC) machines are becoming increasingly important in industrial automation. Featuring fast and reliable networking, python programming and industrial-grade design, the IG902 IoT edge gateway offers remote monitoring solution to the CNC machines, significantly saving both manual labor and costs.

Background

Modern machining has advanced significantly, marked by increased complexity, precision, machine size, and automation. CNC (computerized numerical control) machine tools are vital for enhancing processing quality and efficiency.

However, CNC machines are expensive, and any damage, decreased production efficiency, or production halt can lead to significant losses. To ensure the proper operation and enable preventive maintenance of CNC machines in various manufacturing plants, a machine tool manufacturer sought a remote monitoring solution.

Customer Requirements

Remote Monitoring and Operation

Achieve real-time monitoring of CNC machining centers, including production status, tool conditions, and machining processes. This facilitates remote operation and maintenance for optimizing production plans.

Enhanced Production Efficiency

Through remote monitoring, reduce equipment downtime, enhance production efficiency, and ensure timely completion of production schedules.

Tool and Consumable Management

Implement remote monitoring of CNC tools and consumables, including lifespan prediction, alerts, and automated reordering. This aims to optimize inventory management and minimize production interruptions.

Anomaly Detection and Alerts

Establish an anomaly detection mechanism to monitor the CNC machining center’s real-time status. Timely alerts and notifications are provided to take prompt actions, reducing potential losses.

Solution

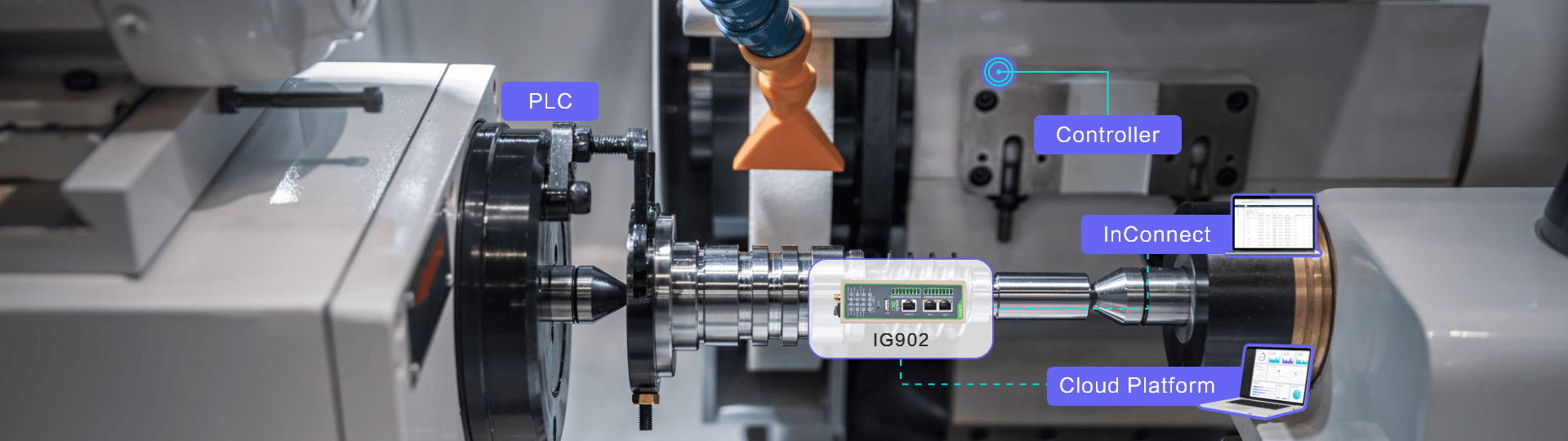

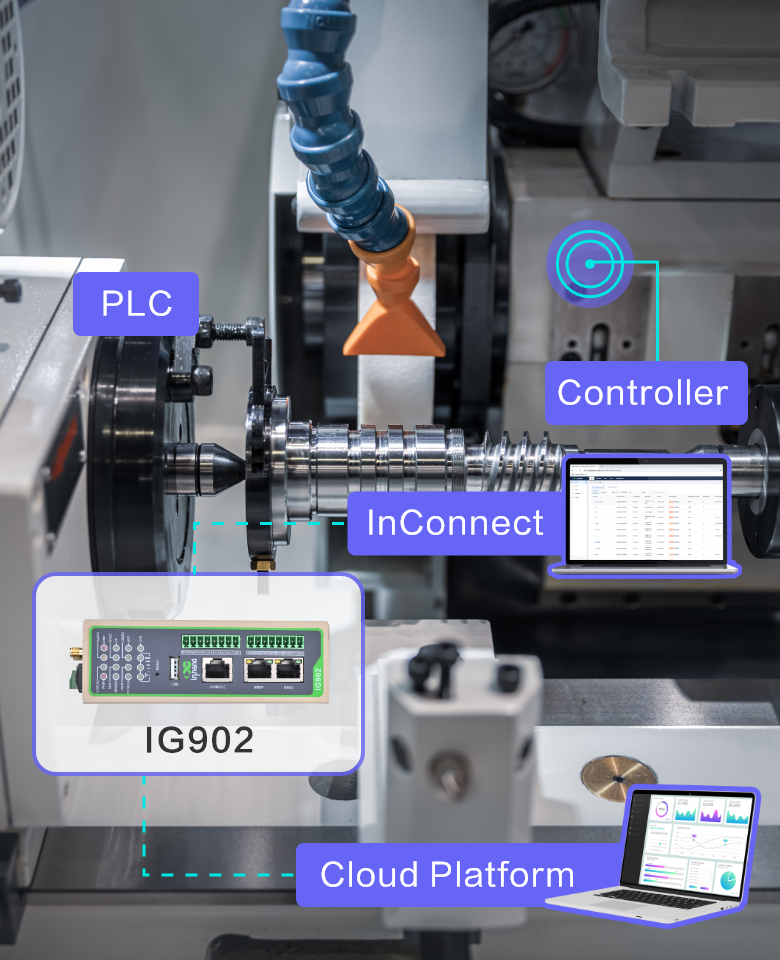

Using IG902 edge gateway, the remote monitoring system connects CNC machines distributed at various industrial sites to the cloud platform, to collect and analyze the machines’ operation status, degree of wear of vulnerable parts, and data of the electric controlling systems.

The IG902 is developed to support edge computing, to perform data acquisition, data monitoring, data filtering, data cleansing, data security protection, data storage, data submission, and logic processing on the front end, reducing the communications bandwidth needed between industrial sites and the central monitoring center, optimizing the cloud computing system.

The IG902 IoT edge gateway provides reliable low-latency communications between CNC machines and the cloud center. Engineers can monitor the real-time operation of the machines, respond to faults with shortened time, and plan for preventive maintenance, saving both manpower and costs significantly.

Benefits

Fast, Secure, Reliable Connectivity

Available with LTE CAT4/CAT1 cellular networks, Wi-Fi and wired connection, multiple link redundancy technologies and security strategies, the IG902 gateway provides fast, secure and uninterrupted network access, ensuring that devices are constantly connected.

Easy Data Acquisition Configuration

The IG902 IoT edge gateway supports multiple PLC protocols and major IoT clouds. Onsite devices can be connected to the cloud through simple configuration in minutes.

Powerful Computing and Intelligent Processing

Built with ARM Cortex-A8 processor, the IG902 gateway features powerful edge computing and data analysis capabilities. Data collected from PLCs can be preprocessed on the edge, relieving the load in the cloud while quickening response to the data source.

All industrial design

Meeting industrial grade on indexes including EMC grade 3, IP30, and wide operating temperatures, the IG902 industrial IoT gateway is solid and durable to withstand the harsh environmental conditions of industrial sites.