Rethinking Quality Control in Modern Manufacturing

For years, sampling inspection has been a reliable quality control method. By checking a portion of products, manufacturers have managed quality risk through statistics.

Today, that approach is being tested.

As factories scale up, product variants increase, and production speeds accelerate, quality expectations have shifted. It is no longer enough for products to be “acceptable.” Manufacturers now expect consistency, stability, and traceability.

Quality inspection is no longer just a final check. It directly affects release decisions, rework, and on-time delivery. This leads to a critical question:

Is sampling inspection still enough for modern manufacturing?

01 When Quality Relies on Sampling

The real risks

In fast-paced production environments, relying mainly on sampling creates clear challenges:

- Quality issues are not continuously visible, and often appear too late

- One missed defect can impact an entire batch, affecting delivery schedules

- Production teams rely on manual experienceto compensate, increasing uncertainty

Sampling itself is not the problem. The issue is that it was never meant to support end-to-end quality control in complex, high-speed production.

Technically, Carrier Aggregation is a feature that bonds multiple carrier channels together to provide a single user device with higher data throughput and reduced latency. It is a foundational technology for both 4G Advanced and 5G networks.

02 What “100% Inspection” Means Today

In practice, 100% inspection does not mean manually checking every detail of every product.

It means this:

For defects or quality characteristics that can be automatically detected, every unit is inspected.

The difference is simple:

- Sampling checks someproducts

- 100% inspection checks every product

As production volumes grow and takt times shorten, the cost of a single missed defect increases. As a result, per-unit inspection is increasingly becoming a practical requirement, especially in electronics, semiconductors, automotive components, and precision manufacturing.

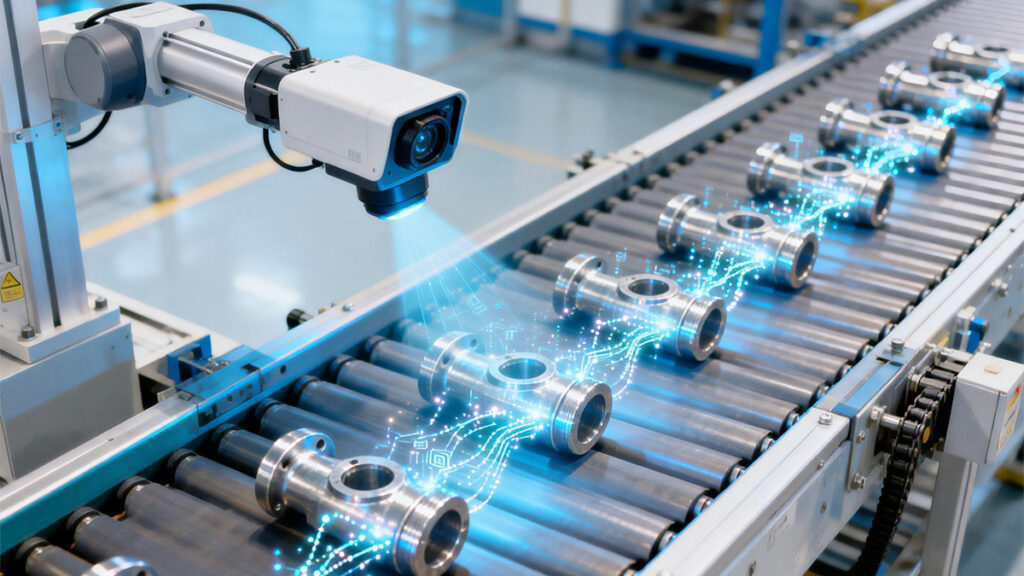

03 Why AI Is Essential for 100% Inspection

Once inspection moves to full coverage, scale becomes the key challenge.

High-speed lines require constant decisions. Multiple product types and processes introduce changing defect patterns. Under these conditions, manual inspection and rule-based systems struggle to keep up.

This is where AI-based inspection becomes essential. Not because it is more advanced, but because it can learn, adapt, and operate continuously at scale.

The focus shifts from whether AI is needed to how it should be deployed to fit real production environments.

04 Making AI Inspection Work in Practice

InHand Networks has developed an AI quality inspection solution designed around production speed, reliability, and long-term operation. The goal is simple:

Make per-unit inspection a dependable part of daily production.

On the production line

To avoid slowing production, inspection must match takt time. High-resolution cameras generate large data volumes, and relying on remote systems can create delays.

In this solution, the EC5550 Edge Computer is deployed directly on the production line. It processes camera data locally and performs defect detection in real time.

Key benefits include:

- Up to 100 TOPS of AI performancefor multi-camera inspection

- Millisecond-level response timesaligned with production speed

- Industrial-grade reliabilityfor continuous operation

With stable, on-site processing, inspection becomes part of the production flow rather than a bottleneck.

Turning inspection data into insight

Per-unit inspection creates value only if results are captured and used.

Inspection data is collected into on-premises systems or a private cloud, creating a continuous quality record. Each product’s status, defect type, and timing can be traced.

By integrating with MES and QMS systems, recurring defects or abnormal trends trigger alerts automatically. Quality control moves from reactive checks to process-level control.

The role of the cloud

In this architecture, the cloud does not handle real-time inspection. Instead, it focuses on:

- Cross-line and cross-factory quality analysis

- Centralized AI model training and evaluation

- Unified model updates

Even if the network is unstable, on-site inspection continues uninterrupted. The edge executes; the cloud improves.

05 What Changes with Per-Unit Inspection?

Moving from sampling to per-unit inspection is more than a technical upgrade. It reflects a shift toward greater certainty in quality management.

The value of AI is not that it appears smarter, but that it helps production run smoothly and predictably. When quality control is based on continuous, reliable decisions—rather than probability—it becomes a system that can support long-term manufacturing operations.

That is the real change.